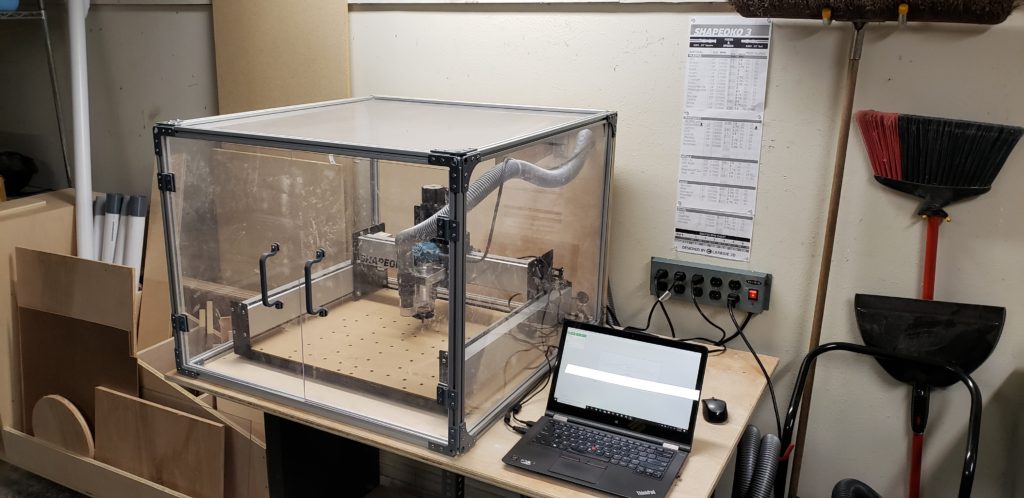

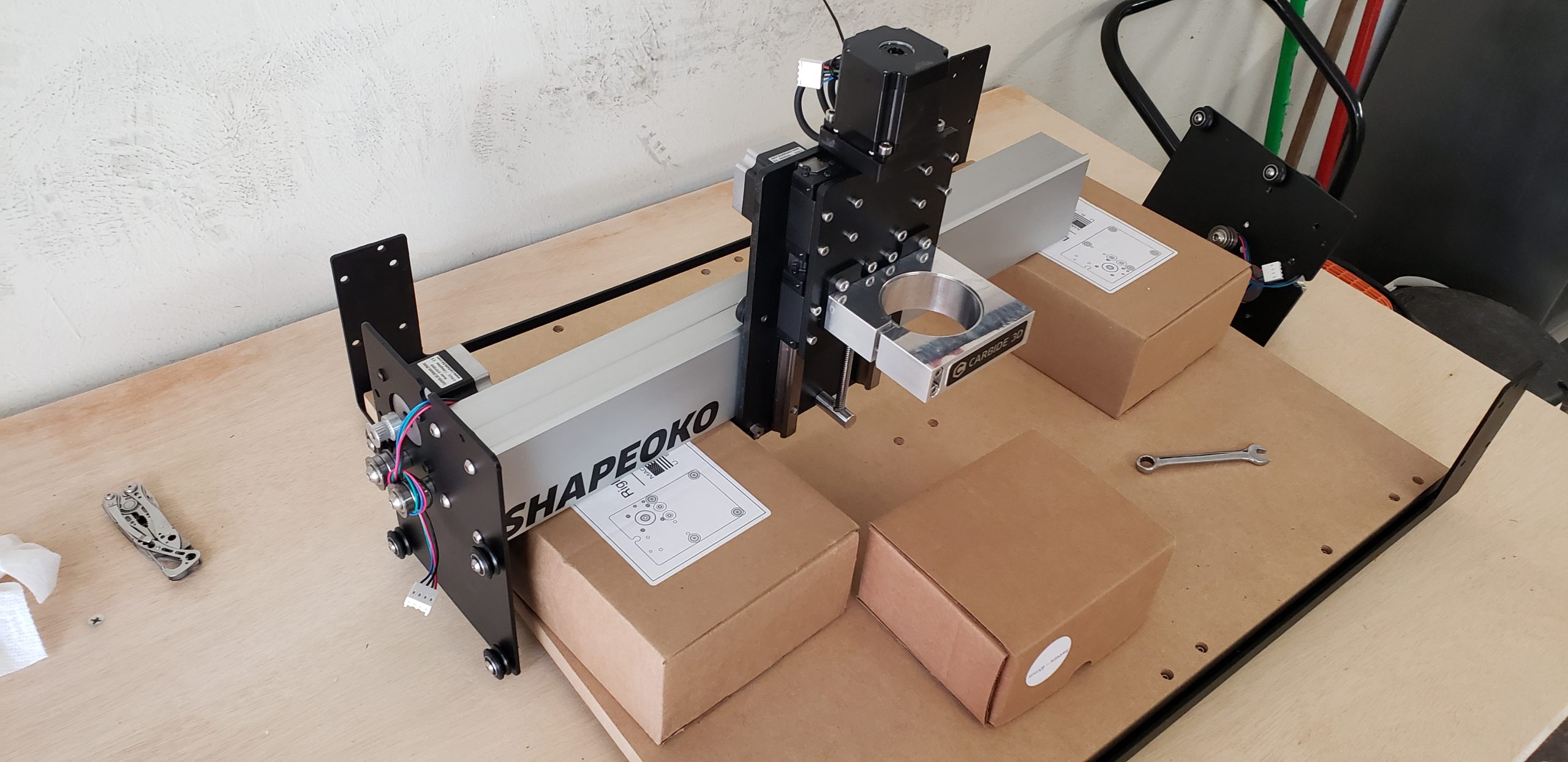

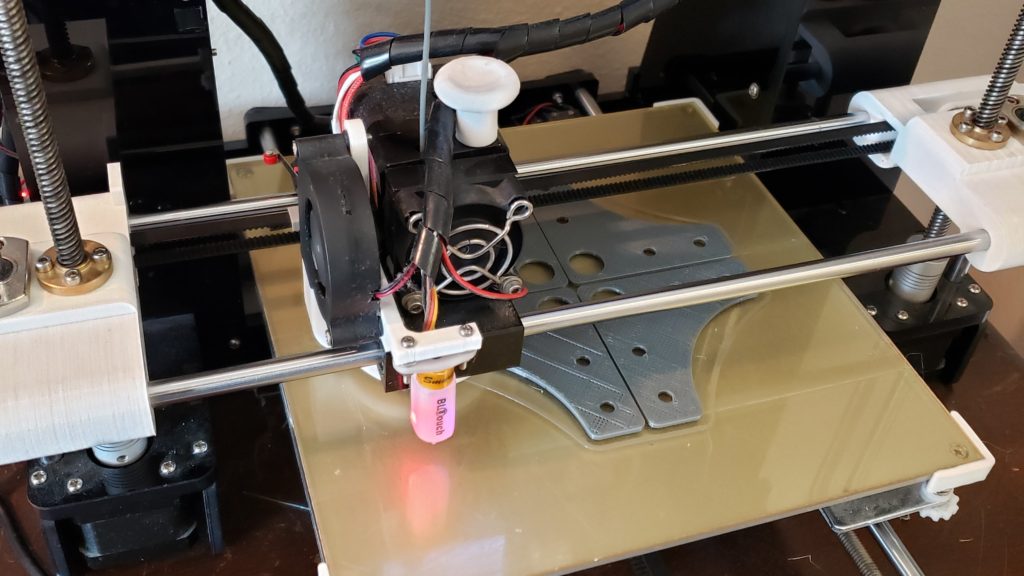

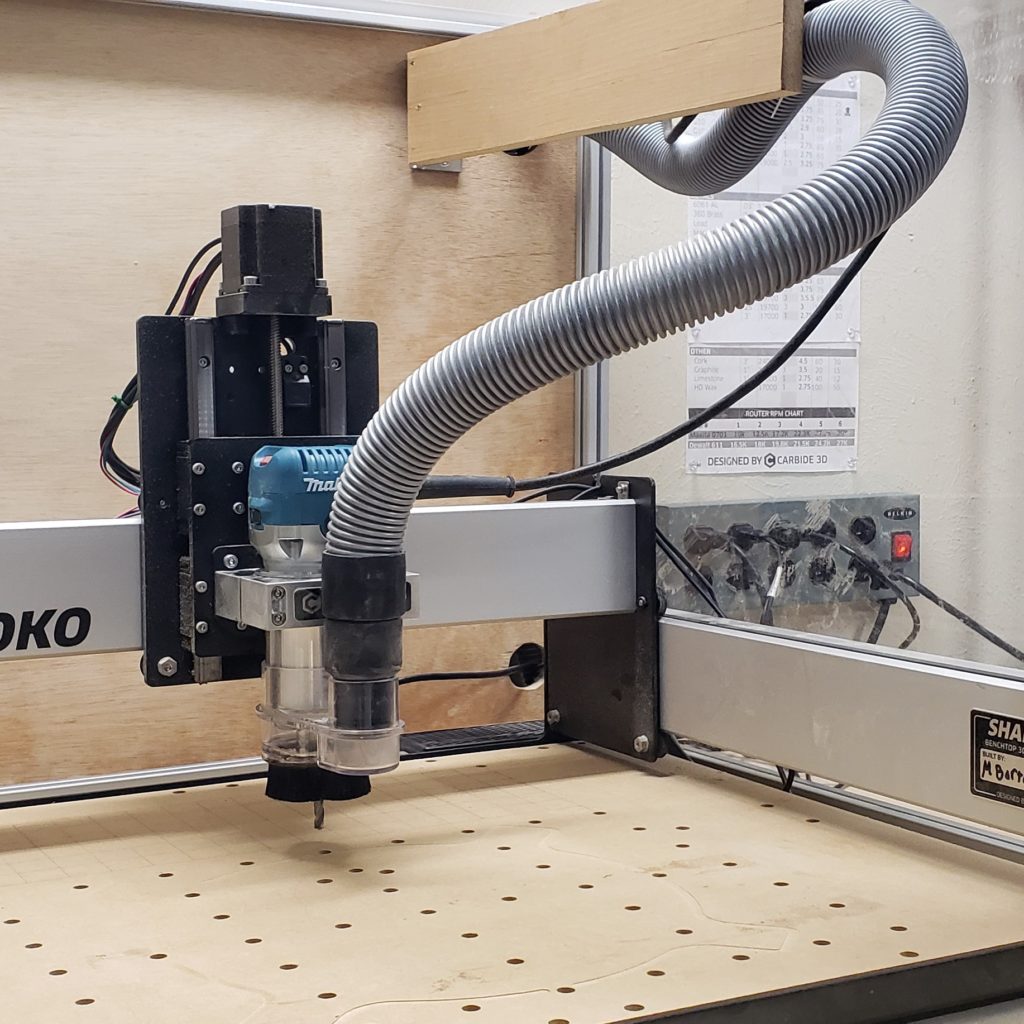

Since I finally decided to pull the trigger and order a CNC router, I decided that I also needed an enclosure to better control dust and noise. I went with a combination of 80-20 aluminum extrusion, 3/16″ acrylic, 3/4″ ply-wood, and 3D printed PLA brackets to design the enclosure. You can find a link to the Solidworks source files below.

The dimensions of the enclosure were selected such that I could cut all the acrylic I needed out of a single 4′ x 8′ sheet. The individual pieces of acrylic sheet were secured by nesting inside the notches of the 80-20 profile. Other parts like door handles and hinges were also 3D printed.

The PLA brackets alone would probably have too much flex in them to make a good, rigid enclosure. Adding the plywood to the back, however, made the enclosure stiff enough.

All of the pieces of aluminum extrusion were cut down to size using a simple hacksaw with a fine tooth blade and a little WD-40.

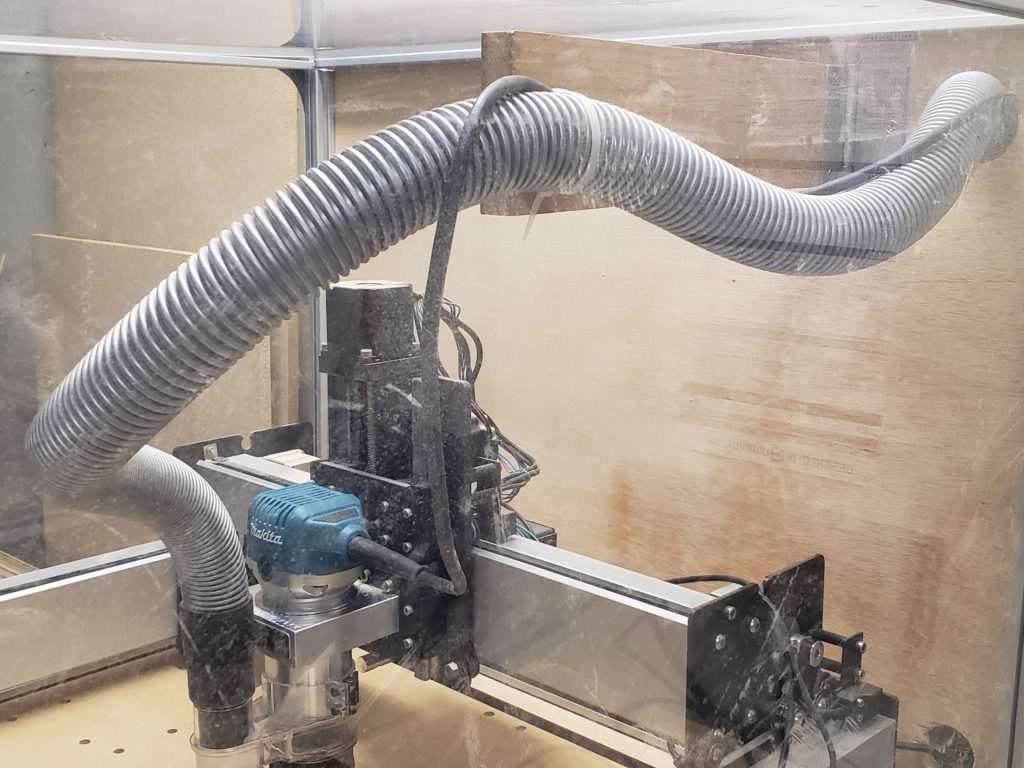

Lastly, I added a piece of 1/2″x4″ wood to the back plywood panel on a door hinge to keep the vacuum tubes and router power up and out of the way while still being free to move with the machine.